All First piece approvals are done after measuring the components thoroughly. We have a CMM from Ziess – Germany, Contura G2, having continuous probe scanning option and Software CALYPSO Curve for reverse engineering.

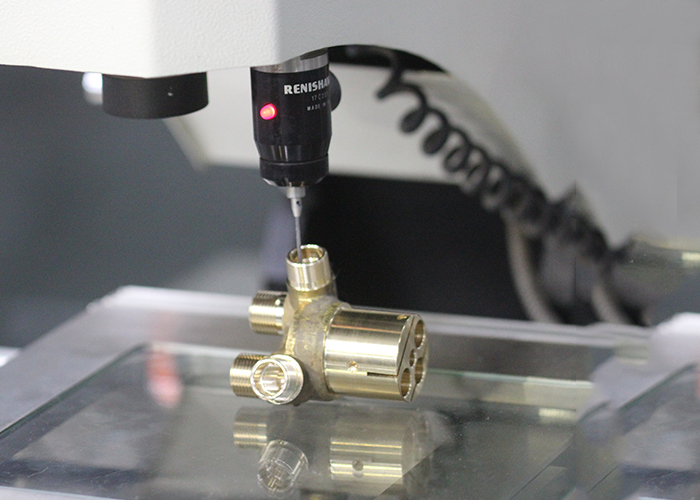

Basic measurements are done with Vision Measuring System with Renishaw Touch Probe. Production Team gets approval only after the component meet the specific requirements as per the drawing.

We have Contourecord 1600G from Ziess-Accretech which enables to measure complex shapes and curves with finest accuracy.

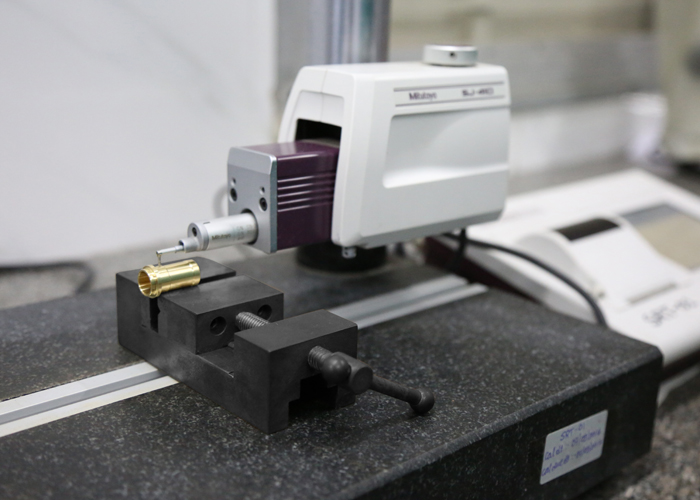

We have Mitutoyo SJ410 for checking surface finish. Reports are generated and print-outs available for records as per customer requirements.

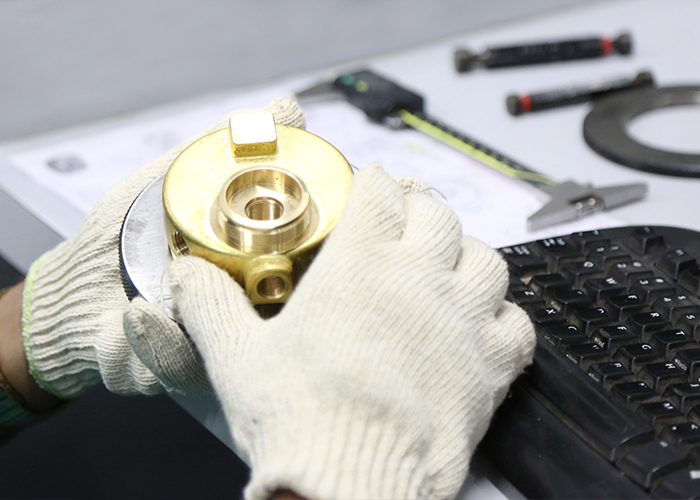

We have shop-floor measuring equipments and master equipments used in our company. Master Equipments are used only by Quality Engineers whereas shop-floor equipments are used by master technicians and technicians. All gauges and measuring equipments are calibrated and we take utmost care of these equipments